ViewMate Pro

Free 30-day Trial

With over 25 years of experience Pentalogix gives you the 10 reasons that separate Viewmate Pro from the rest:

Viewmate Pro Tutorial: Introduction

New Tool Codes Menu

Now Configure All Your Drill and Rout Tool Info Directly in ViewMate Pro

1 Import and export autocad dxf files

You can now use ViewMate Pro to view and edit DXF files. For example, if a board outline is provided as a DXF file, it can be imported into ViewMate Pro. It can then be used to generate the needed fabrication files and also processed using Smart DFM. Users can also export any Gerber layer to a DXF file.

DXF TO GERBER

Sometimes fab drawings are in DXF because the PCB was designed in AutoCAD. Import your DXF file into ViewMate PRO with a few clicks of the mouse. Once loaded into ViewMate PRO, you can edit the data and save as an extended Gerber file or export your changes back to DXF.

GERBER TO DXF

This can be useful for editing Gerber data in AutoCAD, which may have more sophisticated geometrical tools than most CAM systems.

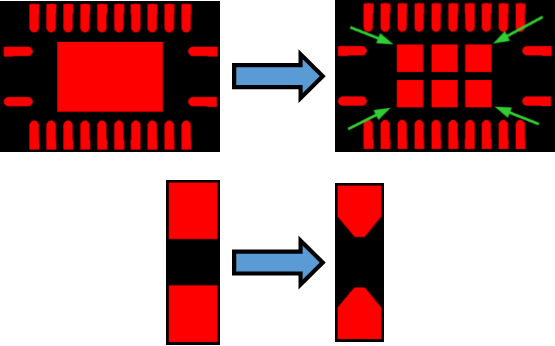

2 Stencil module. It allows generation of stencil shapes from PCB (Gerber) data

- Split pads into "window panes".

- Replace pairs of rectangular pads with "homebase" apertures.

- Create aperture libraries that can be imported and used on future designs.

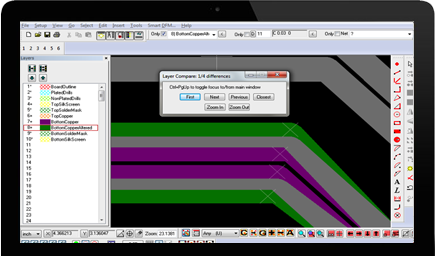

3 Automatic layer to layer comparison

- Use the layer compare function to compare two layers.

- Ensure that a new revision of the design does not differ in connectivity except in the areas where you expect changes.

- Compare "Element by Element" or by "Copper Area".

- You can compare multiple sets of layers at one time.

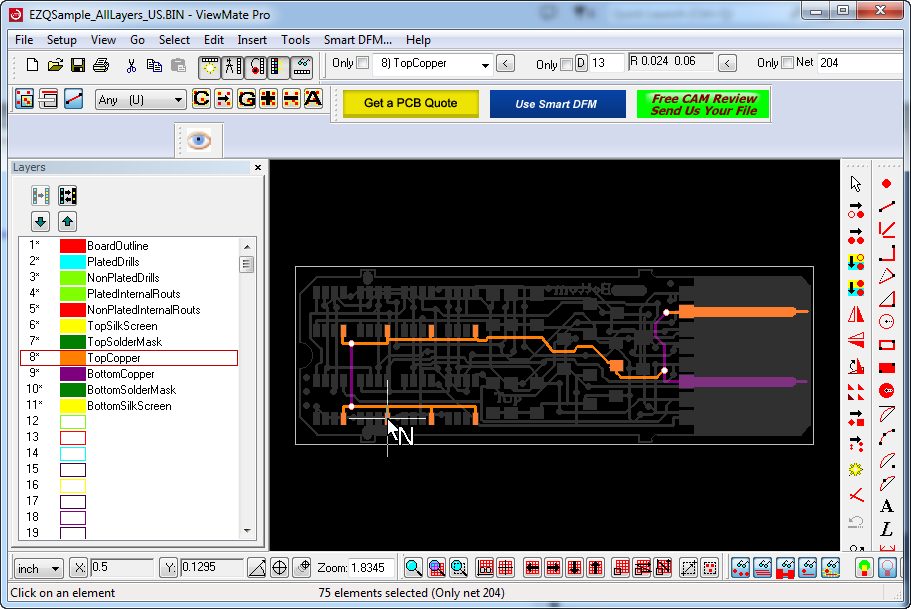

4 Ability to select electrically connected elements

- With this feature, you can click on any element and highlight all of the elements that are electrically connected to that element.

- This feature works across multiple layers and uses available drill and via layers to determine multilayer connectivity.

- Change the display mode to grey out all elements that are not part of the selected net. The selected net will show up in the individual layer colors where the net elements are located. This makes it very easy to see the structure of an electrically connected net.

5 Import netlist files (IPC-356A)

After import, netlist connectivity can be inspected in the main view using net names.

6 Clean up Gerber Data and Reduce File Size

- Many Gerber files contain extraneous elements that make your file much larger than needed.

- Reduce file size by finding and deleting duplicate and/or covered elements.

- Convert areas filled with traces to filled polygons. This can dramatically reduce the size of your file without changing the connectivity of the data.

7 Convert Pads Layers To Drill Files and Sort Drill Data

- Use ViewMate PRO to convert a Gerber pad layer to an NC drill layer with a couple of clicks of the mouse. Round circular pads are automatically converted to NC Tool codes.

- Sort your drill data to reduce the time it takes to drill your drill data.

8 Compute the copper area of layers

- Get an accurate calculation of the copper area of any layer.

- For boards with multiple layers, you can choose to include the area of the barrels that connect the layers.

9 Clip silkscreen layers

- Silkscreen that covers openings in the board can cause problems.

- Use this feature to remove the silkscreen from holes and other openings in the board.

- You can use the solder mask layer as a guide to clip the silkscreen. Clip the silkscreen a specified margin from the solder mask elements.

10 Create Solder Mask and/or Solder Paste Layers

- Don't have a solder mask or paste layer?

- You can set up your selection criteria to select component pads from the top and/or bottom copper layer.

- Transfer these pads to a new layer.

- Swell and/or shrink the pads as needed to create the new mask and/or paste layer.