The PCB Analyzer is an essential tool for ensuring quality and efficiency in PCB manufacturing. It organizes and renames customer-supplied data layers, making them easier to interpret and process automatically. This eliminates common confusions and errors in layer identification.

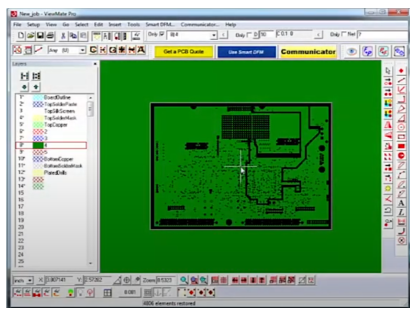

It allows for the setup of complex drill data, providing a clear graphical representation of the drill stack-up. This is crucial for jobs involving blind and buried via layers.

The PCB Analyzer is an essential tool for ensuring quality and efficiency in PCB manufacturing. It organizes and renames customer-supplied data layers, making them easier to interpret and process automatically. This eliminates common confusions and errors in layer identification.

Software Tips

PCB Analyzer Recommendation

It allows for the setup of complex drill data, providing a clear graphical representation of the drill stack-up. This is crucial for jobs involving blind and buried via layers.

The PCB Analyzer verifies and cleans up the PCB outline by removing duplicates and closing gaps, ensuring a precise contour. It also automatically clips elements outside the specified outline, preventing issues in the final design.

It converts negative layers to positive ones to avoid problems when repeating a design. It performs custom DFM checks to ensure the design is ready for manufacturing. Additionally, it clips silk screen data according to defined margins on both the top and bottom layers.

Finally, it extracts standard IPC-356 and PentaLogix F04 netlists, making it easy to navigate and verify the design across multiple layers. We recommend ViewMate users utilize PCB Analyzer to optimize their processes, improve accuracy, and ensure the quality of their designs.

- Organize Layers

- Set Up Drill Data

- Verify PCB Outline

- Clip Data to PCB Outline

- Convert Negative Layers to Positive

- Perform Custom DFM Rule Checks

- Automatically Clip Silk Screen Data

- Extract IPC-356 and F04 Netlist