Imagine this situation: you had a great idea for a new electronic device or product, you have finished your schematic and completed the layout of your Printed Circuit Board (PCB). Now it’s time to send it to the manufacturer.

No matter how good you are at electrical engineering or PCB design, you should always make a small batch of prototype PCBs before proceeding with a production order.

But what is exactly a prototype PCB? Is it different from a production PCB?

In terms of quality and standards, there’s no real difference between production and prototype printed circuit boards. The key difference when we refer to prototype PCBs is that they are meant to be fabricated in small quantities, optimizing their cost and production time. This is typically achieved by combining your design with others from multiple clients into a larger panel using common specifications (for example, all of them having the same solder mask color, thickness and finish plating).

Thanks to our powerful software tools (ViewMate with Smart DFM and CAMMaster), Pentalogix has developed a greatly automated prototype fabrication process: starting with an individual board order, our software determines not only how much space that board will take on a larger panel, but also what other shapes and sizes of boards will fit with it on that same panel. As a result, the appropriate orders can be combined on one large panel, each order paying only for its occupancy portion of the board. Every order goes through a careful Design for Manufacturability (DFM) check to ensure that your design complies with all the specifications.

The main differences between Prototype PCB and full feature PCB processes are summarized in this table:

| Prototype PCBs | Full Feature PCBs |

| Cost- efficient in small quantities | Best option for medium and large quantities |

| Fast turnaround | Longer lead times |

| Restricted set of specifications | Multiple choice of specifications |

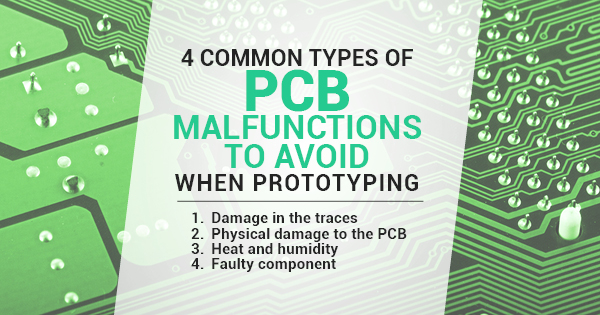

In electrical engineering, there are good reasons to include a prototyping stage in your design process:

- To make a Proof of Concept (PoC): Sometimes you simply want to confirm that your idea makes sense before scaling to a more complex solution. Prototype PCBs are just perfect for this purpose.

- To detect problems with your design: Even if you were careful while designing the board, some things may escape to your attention. A small batch of prototype PCBs is the best method to test the functionality. You do not want to jump directly into a production order for thousands of PCBs only to find out that they all have a short circuit that will make them useless as soon as you connect the power.

- To identify potential improvements: Even if the design works just fine, having the chance to play with a working prototype is often the best way to visualize what could be done better. You may realize that there’s a more convenient location for a connector or a LED, or you find out that you need more digital inputs on your board.

Pentalogix is the leader in fast-turnaround prototype PCB fabrication in North America. Please visit US Quickturn PCB service, where you can get an online quote instantly and order your PCBs in no time.