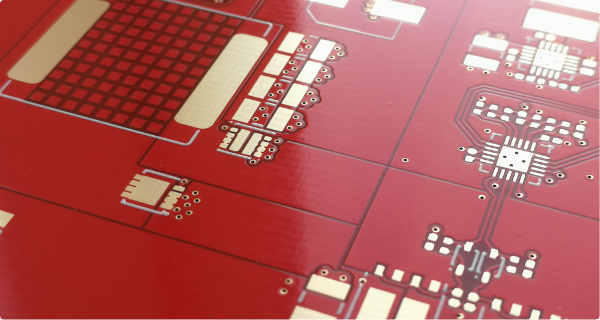

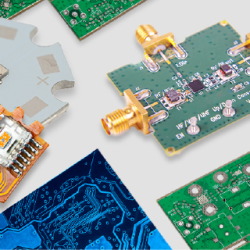

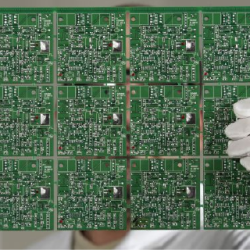

Printed Circuit Board Surface Finishes: A Comparison Guide

When it comes to printed circuit board (PCB) manufacturing, choosing the right surface finish is essential for ensuring optimal performance, reliability, and solderability. The surface finish not only protects the copper traces from oxidation and corrosion but also provides a solderable surface for component attachment. In this article, we will explore and compare some popular PCB surface finishes, their characteristics, advantages, and limitations, to help you make informed decisions for