When it comes to printed circuit board (PCB) manufacturing, choosing the right surface finish is essential for ensuring

optimal performance, reliability, and solderability. The surface finish not only protects the copper traces from

oxidation and corrosion but also provides a solderable surface for component attachment. In this article, we will

explore and compare some popular PCB surface finishes, their characteristics, advantages, and limitations, to help you

make informed decisions for your specific application requirements.

What is PCB Surface Finish?

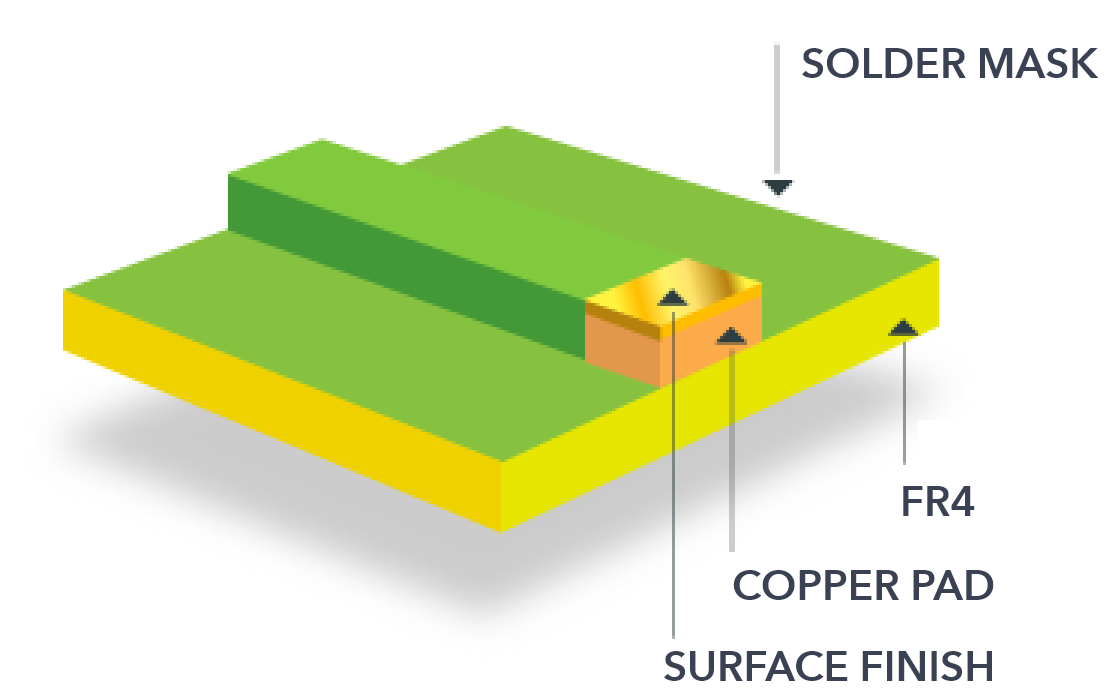

PCB Surface finish refers to the coating or plating applied to the exposed copper surfaces of a printed circuit

board. It serves multiple purposes, including protecting the copper features from oxidation and corrosion,

facilitating solderability for component attachment, and enhancing the overall reliability and performance of the

PCB.

The most common surface finishes available in the PCB industry are the following:

Hot Air Solder Leveling (HASL)

Hot Air Solder Leveling, or HASL, is one of the oldest and most widely used surface finishes in printed circuit board

manufacturing. This process involves immersing the PCB in molten solder and then using hot air to blow off the excess

solder, leaving a relatively flat and solderable surface. HASL provides good solderability and is cost-effective, making

it suitable for general-purpose PCBs. However, it may not be suitable for fine-pitch components due to uneven surfaces

and potential solder bridging.

Lead-Free Hot Air Solder Leveling (LF-HASL)

With the push towards lead-free manufacturing, LF-HASL has gained popularity as a surface finish. It follows a similar

process to HASL but uses lead-free solder alloy instead. LF-HASL provides good solderability, flatness, and is

cost-effective. It is suitable for general-purpose applications and offers compatibility with RoHS (Restriction of

Hazardous Substances) regulations. However, LF-HASL may have higher thermal stress on components compared to other

surface finishes, making it less suitable for high-temperature applications.

Electroless Nickel Immersion Gold (ENIG)

ENIG is a popular surface finish for printed circuit boards, especially for high-reliability applications. It consists

of depositing a thin layer of nickel followed by a layer of gold over the copper traces. ENIG offers excellent corrosion

resistance, flatness, and solderability. The gold layer provides a reliable contact surface for components, while the

nickel layer protects the underlying copper from oxidation. ENIG is well-suited for fine-pitch components, has good

shelf life, and is suitable for multiple reflow cycles. However, it is relatively more expensive compared to other

surface finishes.

Organic Solderability Preservative (OSP)

OSP is a surface finish that involves depositing a thin organic coating over the exposed copper traces. The organic

layer protects the copper from oxidation and provides a solderable surface. OSP is cost-effective, environmentally

friendly, and suitable for fine-pitch components. It offers good solderability and flatness. However, OSP has limited

shelf life, is sensitive to handling and humidity, and may require additional protective measures during assembly.

Immersion Silver (IS)

Immersion Silver is a surface finish that involves immersing the printed circuit board in a silver-based solution,

forming a thin layer of silver on the copper traces. IS offers excellent solderability, especially for fine-pitch

components, and provides a flat surface suitable for SMT assembly. It also offers good electrical conductivity and

thermal performance. However, IS has limited shelf life and is susceptible to tarnishing over time, necessitating proper

storage, and handling practices.

Comparing Surface Finishes

From the previous discussion, it is clear that each kind of finish has pros and cons. The following table compares these

surface finishes based on their solderability, flatness (or planarity), shelf life, corrosion resistance and

manufacturing cost.

| Surface Finish | Solderability | Flatness | Shelf Life | Corrosion Resistance | Cost |

|---|---|---|---|---|---|

| HASL | Good | Poor | Long | Moderate | Low |

| LF-HASL | Good | Poor | Long | Moderate | Low |

| ENIG | Excellent | Excellent | Long | Excellent | High |

| OSP | Good | Good | Limited | Moderate | Moderate |

| IS | Excellent | Good | Limited | Good | Moderate |

Selecting the best surface finish for your printed circuit boards

Pentalogix has been a leader in PCB fabrication for years. We offer all the surface finishes mentioned in this article.

If you are unsure of which type of surface finish is best for your next PCB project, our team of experts can help you

choose the most optimal option based on your budget and technical requirements.

PentaLogix offers PCB manufacturing and PCB assembly services. You can get a PCB quote online or request a custom quote by simply sending an email to support@pentalogix.com.