In today’s rapidly evolving technological landscape, printed circuit boards (PCBs) are the hidden figures that power our electronic devices, from smartphones to space rockets. As we continue to demand smaller, faster, and more powerful electronic gadgets, the PCB fabrication industry is at the forefront of innovation. In this article, we’ll explore the exciting emerging technologies and trends shaping the future of PCB fabrication.

Miniaturization and High-Density Interconnects

One of the most prominent trends in PCB fabrication is the relentless drive towards miniaturization. As consumers and industries demand smaller and more portable devices, printed circuit boards need to keep up. To achieve this, manufacturers are developing high-density interconnect (HDI) PCBs that allow for more components to be placed on smaller boards.

HDI PCBs feature finer trace widths and spaces, micro-vias, blind and buried vias, and higher layer count, enabling the integration of advanced functionalities into compact spaces. These boards are essential for the development of devices like wearables, IoT sensors, and 5G communication systems.

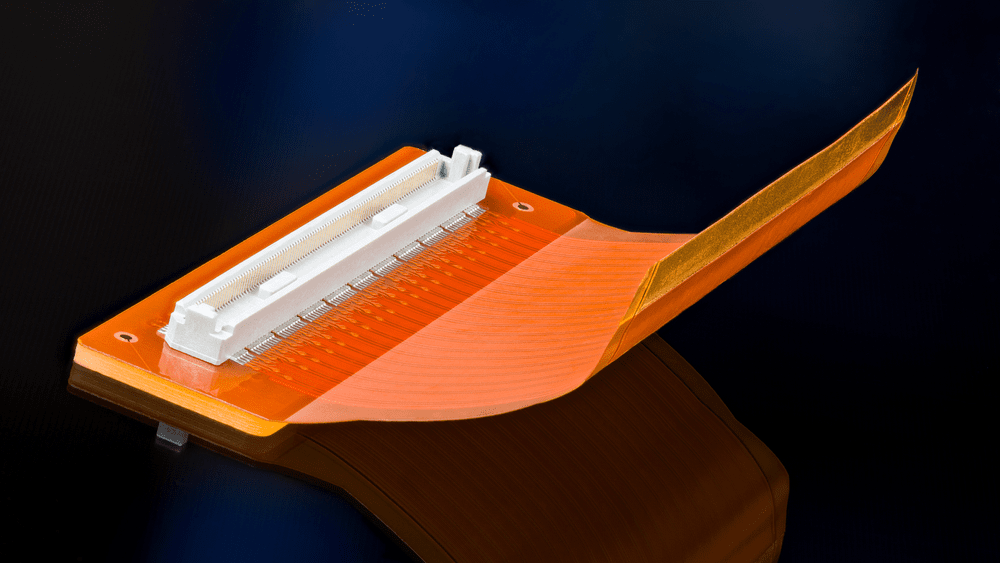

Flexible and Rigid-Flex PCBs

Flexible PCBs are becoming more popular every day. What was a rare requirement some years ago, is very common now and it is expected to grow in the incoming years. Manufacturers know this and have extended their flexible capabilities to keep up with this increasing demand.

Flexible boards are designed to bend and conform to various shapes, making them ideal for applications in automotive, aerospace, medical devices, and consumer electronics.

Flexible printed circuit boards, often made from polyimide, enable curved and flexible designs that can withstand vibrations and shocks. Rigid-flex printed circuit boards, which combine flexible and rigid sections, provide the best of both worlds, allowing for complex 3D designs with improved durability and reliability.

3D Printing for PCBs

While traditional printed circuit board fabrication methods involve layering materials on a flat substrate, 3D printing is emerging as a disruptive technology in this space. 3D-printed PCBs enable the creation of intricate and customized designs that were previously challenging or impossible to achieve with traditional manufacturing methods.

This technology not only reduces material waste but also accelerates prototyping and lowers production costs. As 3D printing technology continues to advance, we can expect to see more innovative PCB designs and applications.

Advanced Materials

The choice of materials plays a crucial role in PCB performance and functionality. Emerging trends in PCB fabrication include the use of advanced materials like liquid crystal polymer (LCP) and high-temperature laminates. LCP PCBs offer excellent electrical properties and are well-suited for high-frequency applications, such as 5G and satellite communication systems.

Moreover, eco-friendly materials and processes are gaining traction as the electronics industry becomes more environmentally conscious. Manufacturers are exploring alternatives to traditional materials that are more sustainable and recyclable.

Integration of AI and Machine Learning

Artificial intelligence (AI) and machine learning are revolutionizing printed circuit board fabrication in several ways. These technologies are used for quality control, process optimization, and predictive maintenance in manufacturing facilities. AI-driven algorithms can detect defects in real-time and adjust production parameters to minimize waste and improve yield.

Additionally, AI and machine learning are used in printed circuit board design to optimize layouts, minimize signal interference, and enhance overall performance. As these technologies become more sophisticated, we can expect even greater improvements in PCB design and fabrication processes.

Green Technologies

As sustainability becomes a global priority, PCB fabrication is also undergoing a green transformation. Manufacturers are adopting eco-friendly practices, such as recycling waste materials, reducing energy consumption, and using environmentally friendly chemicals in the production process.

Moreover, consumers are becoming more conscious of the environmental impact of electronic devices. Companies that prioritize sustainability in printed circuit board fabrication will likely gain a competitive advantage in the market.

PCBs are the substrate technology of the future

As we’ve explored the emerging technologies and trends in PCB fabrication, it’s clear that these boards are at the heart of our technological evolution. The future promises even smaller, more powerful, and environmentally friendly printed circuit boards, shaping the devices that define our lives. From the smartphones that keep us connected to the electric vehicles revolutionizing transportation and the medical devices improving healthcare, these circuit boards will continue to play a vital role in the future.

PCBs are, both literally and metaphorically, the substrate of the future technologies.

PentaLogix offers PCB fabrication services and PCB assembly services. You can get an online PCB quote, request a custom quote by simply email your design files to support@pentalogix.com.