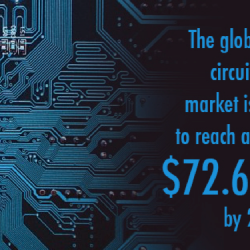

How to reduce PCB Fabrication Costs

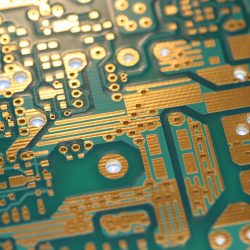

The goal of every engineer or product designer is to achieve the best possible result with the lowest possible cost. Printed Circuit Board (PCB) design does not escape this universal law. This article discusses the best strategies to reduce the cost of producing PCBs without compromising board quality or functionality and illustrates these strategies with simulated examples using Pentalogix PCB fabrication services. PCB Size Printed circuit boards and real estate