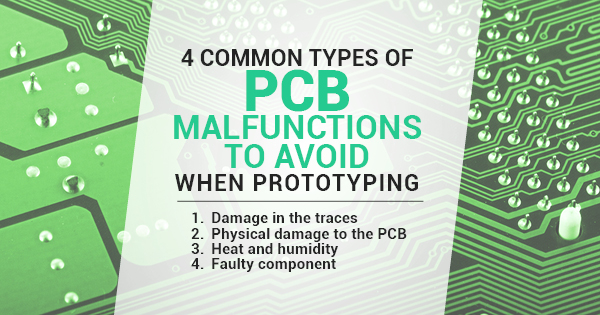

Printed circuit boards are typically in high demand due to the number of industries and businesses utilizing prototype PCBs and their assembly. Because of the time that goes into the creation of these circuit boards and the intricacy of their fabrication, it’s important for prototypes to be created prior to the final design and assembly.

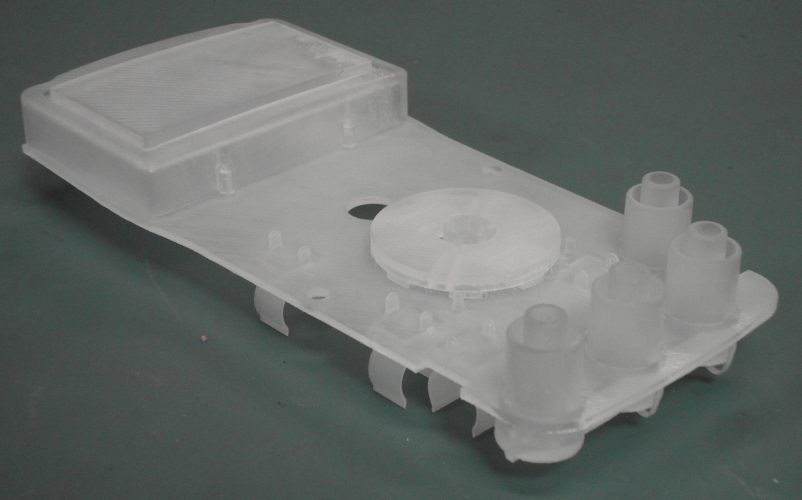

However, the creation and design of printed circuit boards can be tremendously challenging due to the board’s incredibly small size. For instance, just the surface mount of a printed circuit board is only the size of one-tenth of a through-hole circuit. To assemble 0201 packages that are a mere 0.01 inches takes incredible skill. Fortunately, 3D printing is making the design and creation of these impossibly small but necessary printed circuit boards easier to assemble.

How 3D printing is changing the PCB industry

3D printing has been taking the world by storm with its possibilities: Medical practitioners across the globe have been using it to print cheaper emergency medical materials; astronauts have been using it to save space on the space station by printing only the materials they need; and hair researchers have been using it to create scalp prostheses.

Now, 3D printing can be used to help develop and print a prototype printed circuit board, but with multiple benefits including:

- Reducing the size of the prototype printed circuit board. It may seem impossible to reduce the size of a prototype printed circuit board that is already incredibly small. However, as long as the surface is capable of being printed, a 3D printer can create it regardless of size or shape.

- Increasing the surface area of the PCB layout. When a printed circuit board is crafted by hand, there are only two layers available for designing surface mounted technologies. However, 3D printing enables the ability to embed the components of the PCB so as to increase the surface area of the outer layers for the components that need cooling.

- Increased diversified materials. When PCB manufacturing is done by hand, technicians can only use the materials available to them. However, with 3D printing, any material can be printed as long as it’s able to be suspended in ink. Therefore, the printed circuit board is capable of being flexible or as brittle as necessary for the design.

Just as 3D printing is doing wonders for other industries around the globe, so can 3D printing bring promising possibilities to the PCB industry. As the technology develops further and becomes more advanced, the PCB industry may be able to create prototype circuit boards smaller and more complex than ever before.